Digital Twin for increased Project and Operational Performance

Elements of a Digital Twin include a control system simulator, Mimic simulation software for I/O and process modeling.

Aspen HYSYS Dynamics process models, Mimic Operator Training Manager, Mimic Test Bench for control system testing and check out, VR immersive simulator for field operator training and virtualisation to host locally on site or in the cloud.

Digital Twin technology can help improve performance across the supply chain of a production process. Starting from capital project execution right through to repetative operations.

Aspen Plus is continually upgraded with leading innovations in modeling capabilities—ensuring an improved user experience, up-to-date property data, and even more precise modeling.

Comprehensive for the Energy Industry

Optimise upstream, midstream and refining processes in one environment. Integrate models from gathering networks to processing facilities. Sustain refinery profits with faster updates to planning models.

Operational Decision Support

Model the lifecycle from design through operations for faster troubleshooting, online performance monitoring and real-time optimisation

Most Trusted Process Simulator

Rely on the most requested process simulator that has been trusted for over 35 years. Experience the latest innovations in process simulation.

Uniquely designed to take process flows into account, the solution identifies the impacts of failures, upgrades and repairs on overall performance and revenues. This can help create greater mine-to-mill alignment, Ensure that decisions made during extraction don’t negatively impact processing or recovery.

Reliability, Availability & Maintainability

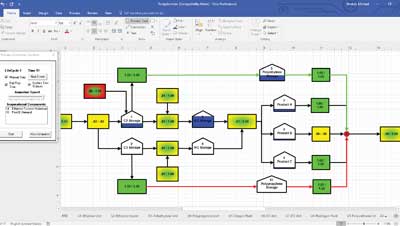

Aspen Fidelis is a reliability management solution that is uniquely designed to take process flows into account, and the impacts of failures and repairs on overall plant performance and revenues.

Aspen Fidelis Reliability is a discrete event simulation modeling tool, utilising Monte Carlo simulation to model all of the probable future performance metrics of complex, large-scale asset systems. Aspen Fidelis Reliability is unique among stochastic or dynamic simulation software tools in its ability to handle any complexity. This eliminates uncontrolled assumptions, which compromise the accuracy of results. These complexities are typically an inherent part of systems, and are easily modeled by Aspen Fidelis Reliability, generating outputs that support more profitable decision making.

ARC View:

Digital Twins Support Supply Chain Optimisation

Aspen Fidelis

Reliability has demonstrated the

ability to reduce CAPEX for new

projects by more than 5% and/or

increase production by more than 3%

by giving insight into availability.

System Reliability Modeling

The behavior patterns for events involving the plant and its equipment (pumps, motors, weather impacts, operational upsets, etc.) are represented by probabilistic distribution functions. Fidelis takes samples from these distribution curves and derives a “time to failure” estimate. When an event leads to a failure of a piece of equipment, there will likely be impacts to the wider system, including the unit to which the piece of equipment is attached and other units or equipment that are upstream and downstream. Fidelis can also model flow through the pipes, tank levels, as well as the utilised and available capacities of all units. In addition, any required custom logic — such as dynamic batching, seasonal changes, alternate flow paths, non-time-based failures, conditional logic and equipment aging — can be incorporated into the model. If you can describe it in words, Fidelis can model it!

Fidelis provides a comprehensive bad-actor list and quantifies maintenance and downtime costs as well as potential lost revenue. As a result, you can more effectively perform lifecycle analyses on assets, including asset utilisation, maintenance effectiveness, overall equipment effectiveness and much more. With Fidelis, decision-makers can maximise the ROI with models and predictions for individual pieces of equipment as well as the whole system.

Key Benefits for Your Business

With Fidelis, you can bring a unique set of benefits to your customers and your bottom line. In short, you can realize new revenue streams across the lifecycle of every asset.

During the design phase of any project (greenfield or brownfield upgrades), you can utilize Fidelis as a design aid to ensure that the right decisions are made from the beginning. In addition, Fidelis can be carried forward into operations. During this phase, customers need to continue making optimization, debottlenecking and maintenance decisions, including setting spare part inventory levels. Fidelis can be used throughout the entire lifecycle to maximise production, minimise risk, create new revenue streams and build longer, stronger relationships with your owner-operator customers.

Using Fidelis Throughout the System Lifecycle

- Design Aid

- Life Cycle Cost Evaluation

- Supplier Selection

- Initial Maintenance Concept

- Initial Spares Provisioning

- Living Models

- Maintenance Optimization Debottleneck Analysis

- Evaluating Operating Procedure

- Ongoing Sparing Decisions Identification of Key Coast and Performance Impacts

- Logistics

- Establish Priorities for Analytics Deployments

- Cost/Benefit Analysis of Proposed Engineering Changes

- Evaluate Proposed Changes in Usage

- Effects of Aging on Continued Support